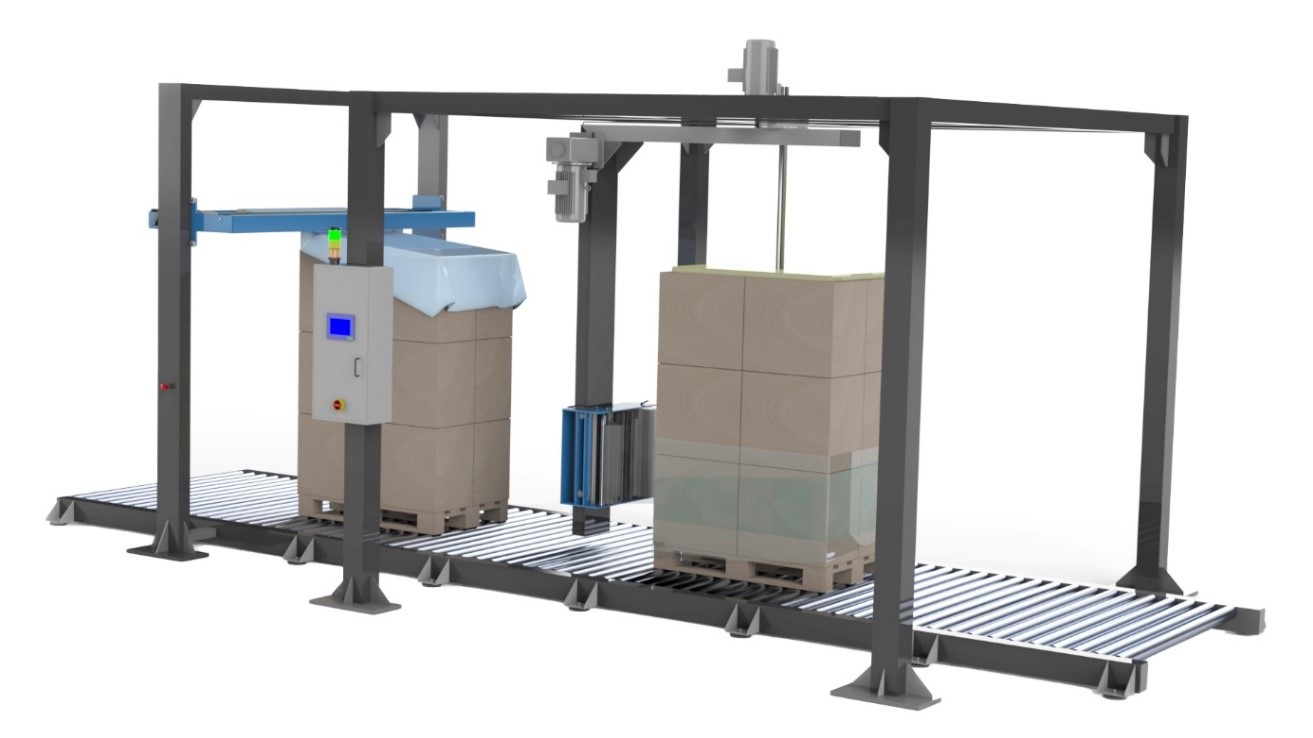

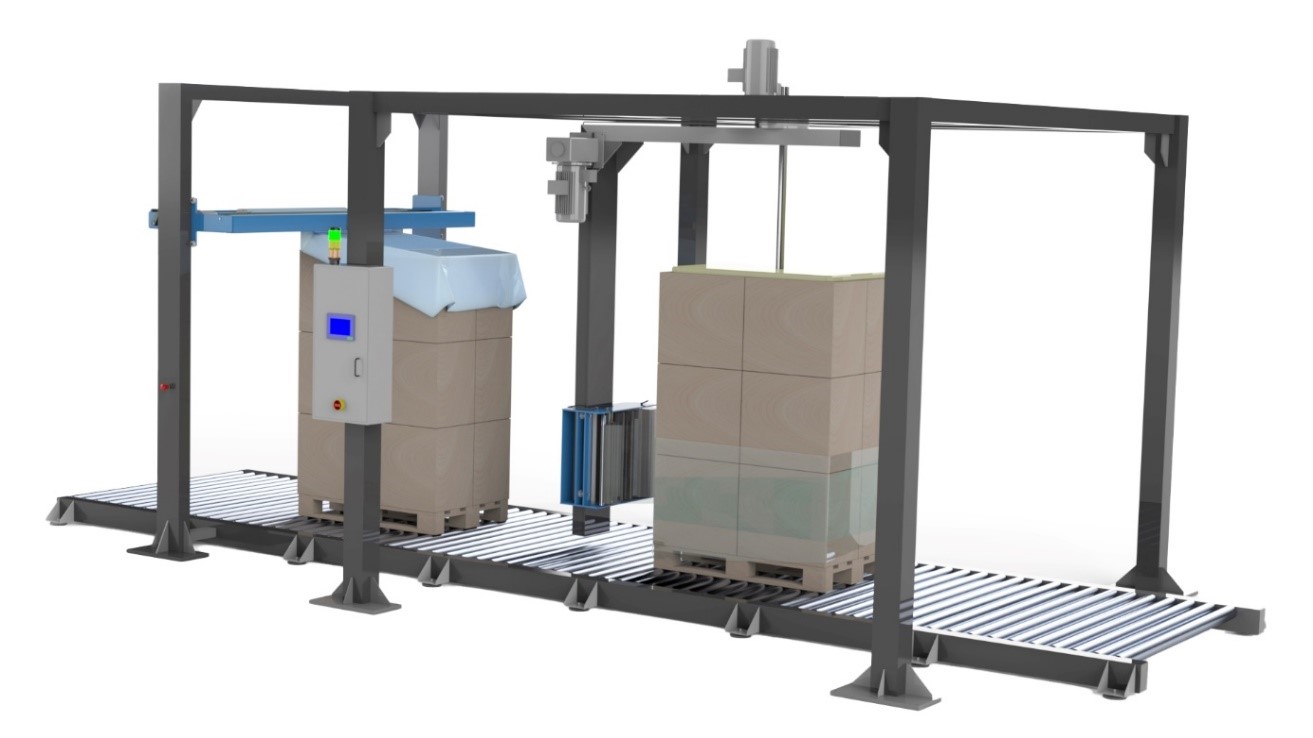

Static free high speed (in-line) pallet wrapping

Manually placing boxes on pallets and wrapping them can be time consuming and expensive. For this reason this process is often completely automated. Automated pallet wrapping lines come in a wide variety and always have one thing in common: problems with static electricity on the stretch and/or the top foil.

Stretch wrapping machines are used to wrap stretch film around a loaded pallet. Stretch pallet wrapping is widely used in general, food, chemical and electronic industry. A highly stretchable plastic film, commonly made from Linear Low-Density PolyEthylene (LLDPE), is wrapped around items. The elastic recovery keeps the products tightly bound. Stretch film is used to wrap products on pallets and secure them to each other and to the pallet during transport and storing.

Note: Drawings and pictures do not show the application one to one, but clarify the situation and approach reality

After palletising, a top-foil dispenser can apply a protective sheet over the products to protect them from environmental influences such as humidity and dust. Neutralising static charges directly after unwinding can prevent the protective film from “clinging” and not fully covering the products.

During wrapping of the pallet with a stretch-foil, static charges can create shocks (discharges) to operators, electronic parts or optical sensors and cause dust attraction to the foil. An ultra-compact VicinION 24V static eliminator, mounted on the rotary arm, can neutralise the static charge after unwinding of this stretch film.

Simco-ION can help you solving any specific static problems resulting in high quality competitive packaging production including your wrapping process. Are you interested to learn more about the effects of static electricity?

Find a Simco representative near you or subscribe to the Youtube channel Simco-Ion static control Europe