Chosing the right type of Industrial Static Eliminator

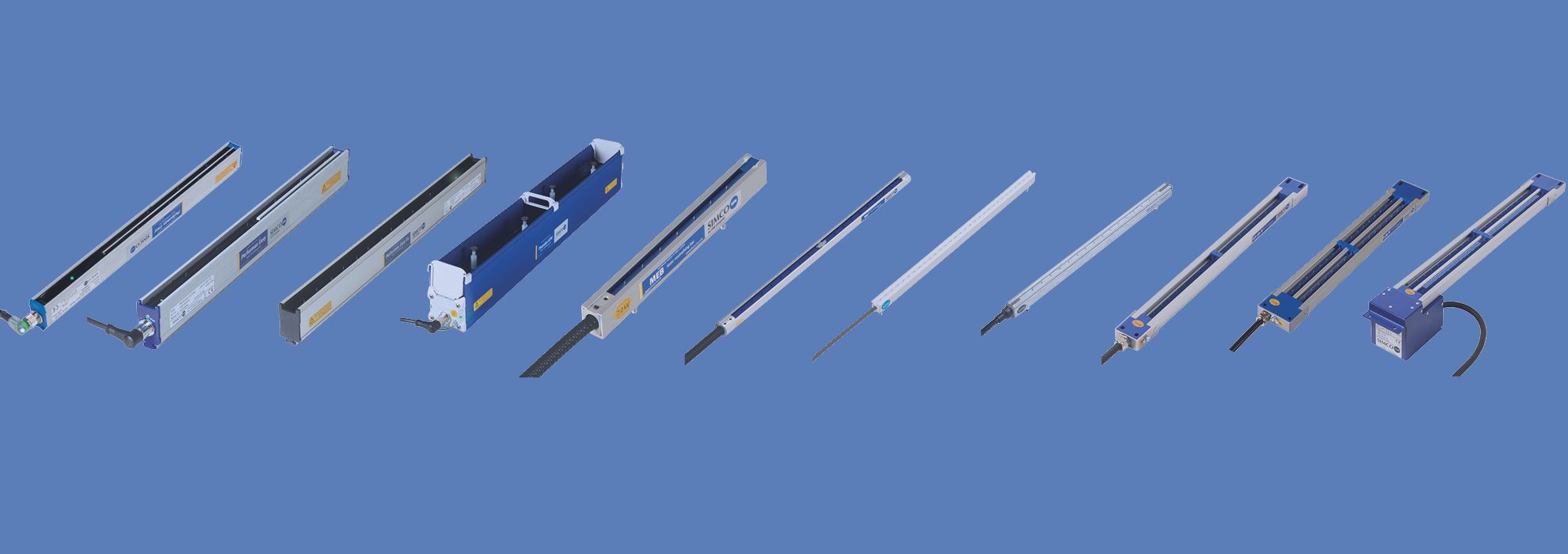

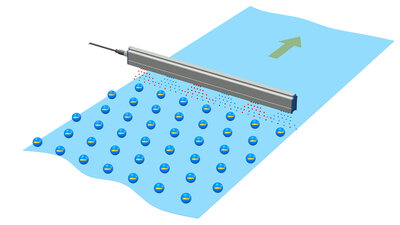

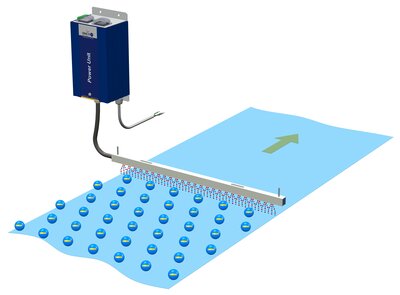

Simco-Ion anti-static bars or industrial static eliminators generate an electrical field which causes the air molecules in the vicinity of the bar to break down into positive and negative ions. The antistatic bars come in different lengths that vary from 20cm up to more than 5 meters depending on the type. Also the housing of the static eliminators ranges from very small (24x27mm) up to larger sizes that allign with the working distance to the material. There are many different Industrial static eliminators and difference between them is found in ;

- How the static Eliminator is powered( VAC-230/110/120 or 24Vdc)

- The distances to the material that needs to be neutralized(short-/middle-/longe range)

- Special Bars( Size of body, special Material, ATEX, UL or Smart Industry 4.0)

Select how the static eliminator is powered.

Static eliminators can be powered by an externalPower Supply that feeds the static eliminator with a high-voltage cable or the bars can be powered with an external 24Vdc cable. With this new technology solutions, the high-voltage power supply is integrated into the bar. This brings the advantage that no high-voltage cables need to be placed in the machine. Below you find the table for selecting the right static eliminator. The 24Vdc Ionisation bars are all made Shockless( no shock when touching) while most of the AC Ionising bars are not.

In both the 24Vdc and the older AC-powered you can chose for for short- and long-range ionisation bars. Smart solutions like inline measuring, feedback compensation, communication to Ethernet and clean-bar-indication are only availble in the 24Vdc selection. Also in both sections bars that have UL-certification can be found.

Go to: 24Vdc powered DC Static eliminators.

Go to: external powered AC Static eliminators.