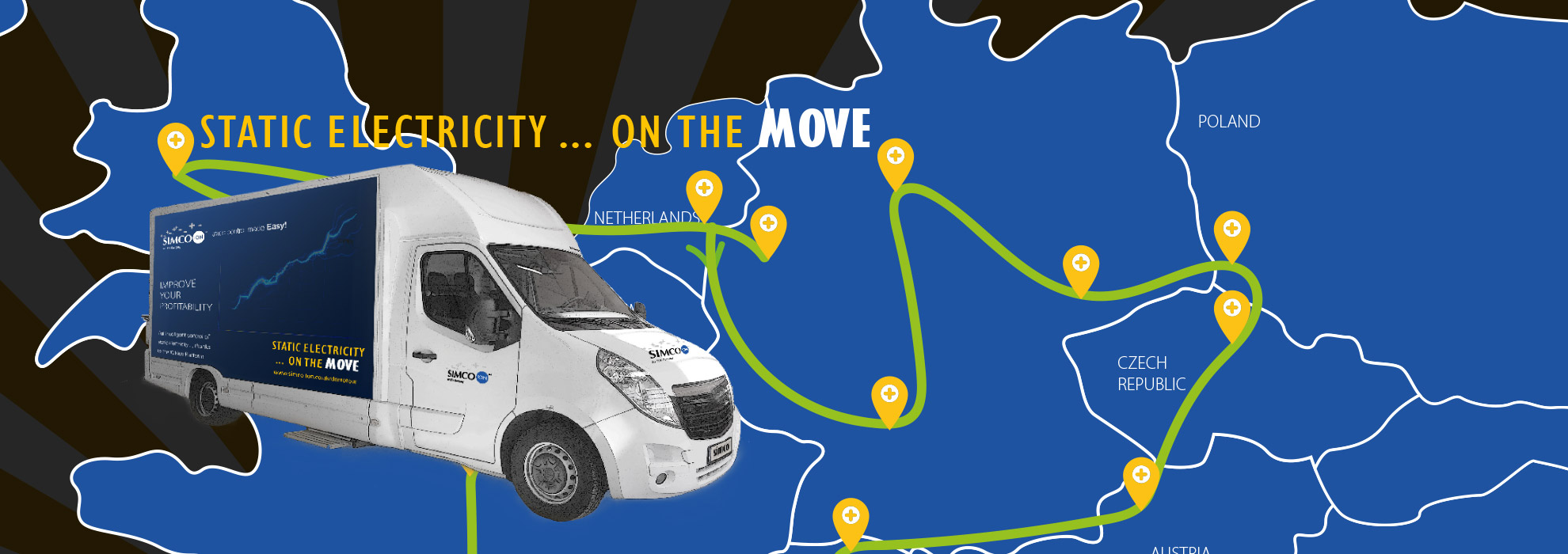

Roadshow with complete intelligent static control, Simco-IOn Roadshow.

Roadshow with the demonstration of Simco Ion full industrial static control with de static products and industrial static eliminators for industry 4.0

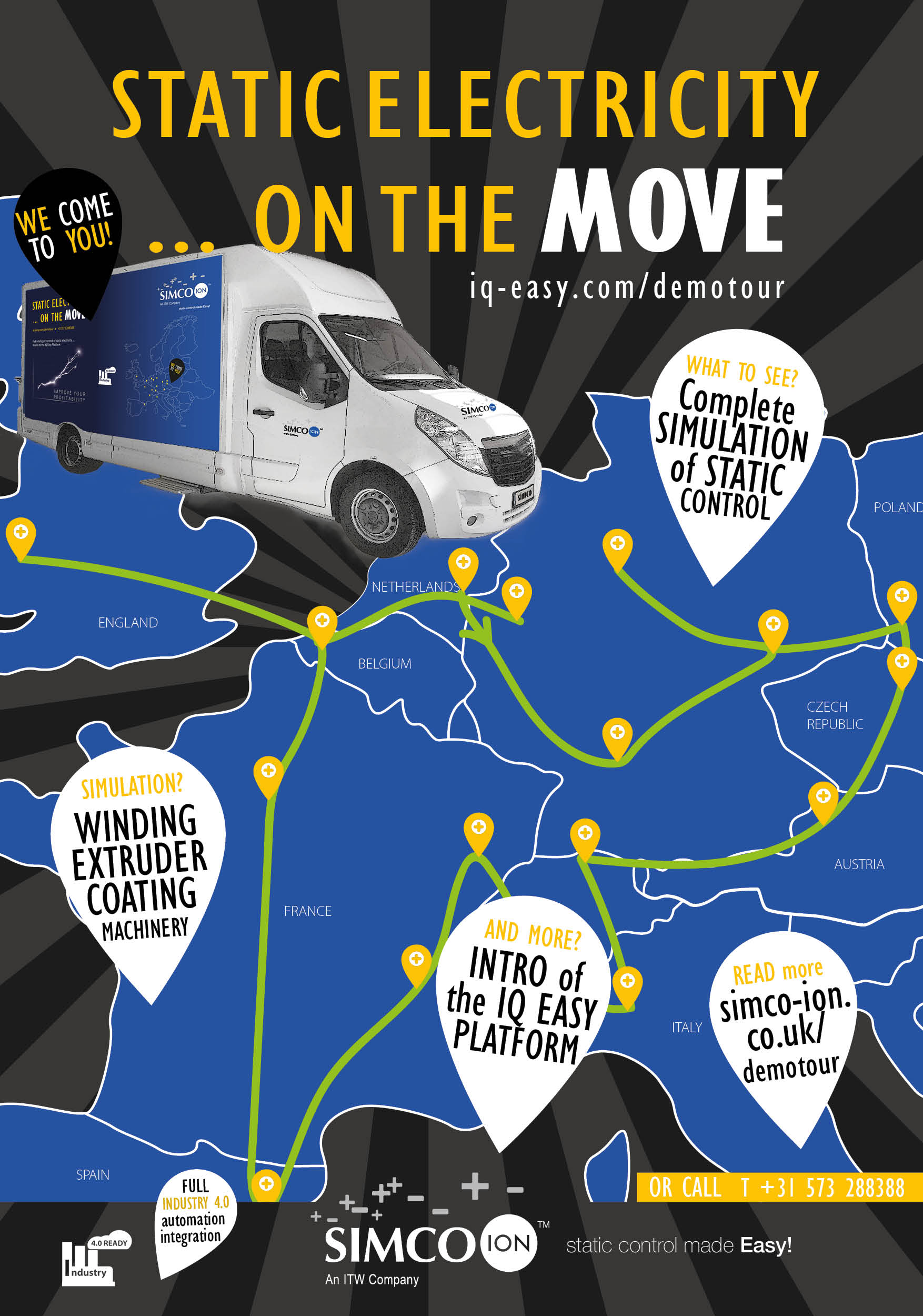

To achieve a full intelligent control of static electricity with the use of industrial static eliminators and de-static bars in your production process Simco-Ion Static Control solutions can help you! You can now see locally our solutions... thanks to the Roadshow with our IQ Easy Platform! Read how the IQ Easy Platform offers a total solution for the control of static electricity and the problems related to static electricity followed by the use of methods and options to eliminate static electricity with the aid of ionisation(ionization) products. The use of air-knifes, air nozzles, and ionizing static control bars and eliminators are demonstrated by our tourbus in the roadshow. Also the use or our electrostatic fieldmeter, the FMX-004, is demonstrated. You can follow the tour through Europe. Or sign up if you are interested in a demonstration, please check it out below!

Touring with intelligent static control.

Started in March 2019, our Simco-Ion Roadshow visits 11 countries throughout Europe, during 10 months, to show a static control simulation and all the industrial static eliminators live and in production.

We started with the Roadshow in March 2019 on the world’s leading exhibition for paper, film & foil converting ICE Europe 2019 in Münich from 12-14 March 2019.

Simco, Simco-ion, static eliminators, industrial, demonstration, on site truck, truck, roadshow, static electricity on the move!

The duration of the Roadshow 2020 is from March to December. The simulation consists of a flat film extrusion, coating process application (ATEX) and a wrapping machine and a winder application. In this imitating machinery are components included that ensure complete control of static electricity by means of inonzing bars static control, our IQ Easy Platform. The material can also be used and will be explained on how to handle with the following processess: gravure printing problems solutions for flow wrap machines, converting equipment, blow molding machines, tampo printing machines, flexo printing or narrow web label printing, in mold labeling generator for IML, (vertical) form fill seal packaging, offset printing solutions, gravure printing problems and solutions, blister packaging problems and high voltage ac power supplies to create solutions

IQ Easy Platform

The IQ Easy platform covers a product range of industrial static eliminators(bars) and charging equipment like high-voltage ac generators of different types from 0-60kV, including special products for IML(IML HV Generators and IML Resin for mould) . A unique concept that makes it possible to fully control all parameters and let devices interact with each other to optimise efficiency and to fully control ionizing static bars:

- Quality assurance by measuring static charges and data logging of values of static electricity. See our about the quaility assurance features of the Manager IQ here

- Optimal control over all levels of static electricity and the industrial static eliminators gives security; Please check our video about the level-controll of static electricity and the reduction to 0kV here.

- The lowest possible achievable residual charges(0kV) enable you to meet the requirements of delivering without static charge;

- Warnings and alarms provide advance information about possible exceedances of critical process parameters. This allows you to take timely measures before your process is disrupted; Check out the video on warnings an alarms here

- Through datalogging and action logging you can track where possible faults at all times have occured.

More information?

If you have any questions about our IQ Easy Platform or the Demotour 2019, please contact the agent in your area or fill in the form below. You can also check all our video's on the features of the Manager IQ Easy Platform, just follow the link here for the complete playlist on youtube.

Roadshow, Simco-IOn on the MOVE

Le Demotruck en Alsace!

16 September 2019

Le Demotruck en Alsace! The last few weeks we had extra visitors than expected thanks to the striking appearance of the truck :) and the beautiful weather in Alsace, France.

We visited two of Amcor's branches and FUJI Seal. A total of 9 companies followed a demonstration. And again, there are very interesting follow-up projects. The demonstration is very much appreciated, it gives a clear picture of the possibilities that Simco-Ion has to offer.

All in all a great success, thanks to our local agent Bruno Defendi and Wouter Halfwerk from Simco-Ion.

Il DEMO TOUR in giro per l’Italia continua!

15 July 2019

From our representative in Italy:

Our staff is introducing to the customers who have given their availability the advanced anti-static system "intelligent" produced by our represented Simco-ION.

Among the many advantages of equipping these devices, and being able to interface them with their PLCs, through the widespread Siemens ProfiNET protocol.

We remind you that the contents of the DemoTour will also be available on the Simco-Ion stand at the K2019 fair in Düsseldorf, which will take place from 16 to 23 October this year!

PROCHEMA, your partner for almost 50 years, has developed industrial applications based on the Simco-ion IQ platform, with ProfiNET interface to Siemens S7/1200 and 1500 PLCs.

The motto is INTEGRATION with existing systems, for an increasingly present INDUSTRY 4.0.

Stay Tuned!

Demotour in Switzerland

5 July 2019

From our representative in Switzerland: Despite hot temperatures and upcoming summer holidays we were able to welcome almost 20 people in our tour bus. Our visitors came from various industries; watch industry, electronics and mechanics.

The visitors to our Swiss salt mines were very special and new territory, so to speak. For the first 2 days the bus stood on our premises in Nürensdorf and on Wednesday evening we changed to Lake Geneva. Our location there was the parking lot of a beautifully situated hotel above the lake. The visitors could enjoy a glass of wine after visiting the tour bus on the beautifully situated hotel terrace.

We had very interesting and exciting conversations with our visitors and were also able to arrange subsequent visits. 3 great projects were also created, such as the unloading of watch dials - just to mention one.

Demotour in Austria

28 June 2019

Polishing and cleaning all the way ready for the next tour! During the tour in Austria every day 3 companies were visited and with lots of demonstrations.

Next country is Switzerland.

Demotour in Czech Republic

17 June 2019

Our customers agreed, the IQ Easy Platform can bring visible improvement to their production."13 companies were visited and the experience was very positive despite the warm weather."

Main benefits according to our customers are the closed looped feed back discharging and the perforation detection!"

In Poland: "Lots of amazing smiles!"

7 June 2019

The Demotour was from May 20. till June 7. 2019 in Poland. More than 200 people visited the Demotruck. And not only on site but also at the Plastpol. The overall reaction on the demonstration was very positive and a lot of amazing smiles on faces! In fact for most of the companies it was also a training about electrostatic and how to solve problems in production lines.

Our representative in Poland: “It was nice to have the Demo Truck and to show not only to maintenance people but also to people from Health and Safety Department, Quality managers and Engineers etc.. It was very positive! I know for sure that at the next Plastpol we would like to have the truck on KM stand to demonstrate in Poland again.”

"13 days of Static electricity ... on the Move - and no time to be superstitious”

17 May 2019

263 people from 15 top companies of the North German mechanical engineering, the packaging industry as well as the film and paper industry were informed in 53 lectures about the possibilities of Simco-Ion's electrostatic high-tech system, the IQ Easy platform.

Practical demonstrations of the technical possibilities via simulation of winding, extruder and coating machines, the participants were able to get an idea of the special requirements and dangers of modern materials in terms of electrostatic and how to get them under control.

In addition, unusual approaches were presented, which could be solved with existing technology but inadequate.

After 3300 kilometers and 280 hours of continuous use of the Demo truck, there is no break: Interested parties want to know more about Simco-Ion’s IQ Easy system and the tour already continues without interruption.

Demo truck in Thuringia, Saxony and Saxony-Anhalt.

26 April 2019

In the first weeks of April, the Demotour of Simco-Ion stopped at film manufacturers and manufacturers of extrusion and winding machines in Thuringia, Saxony and Saxony-Anhalt.

More than 50 participants were shown how ionizers can work optimally in communication with a measuring sensor, how reliable monitoring of the ionization performance is possible and how data (for example via the PLC of the machine) can also be incorporated into the production chain with regard to Industry 4.0.

Demo truck at RKW in Wasserburg

25 March 2019

The Demo truck tours further through Germany, one of the 11 countries that will be visited this year, after the ICE Europe in Munich. After the ICE allready 5 companies with more than 70 interested people joined our demonstration, including RKW in Wasserburg.

RKW showed interest in our IQ products and requested us for advice about the layout and installation of the Simco-Ion equipment in their plant.

The ICE Europe in München from 12 - 14 March 2019

12 March 2019

The start of our Demotour on the ICE Europe in München from 12 - 14 March 2019. Visitors of the ICE were demonstrated how to achieve a full control of static electricity in our Demo truck.