Creating static charged filter material

electrostatically charge non-woven filter materials

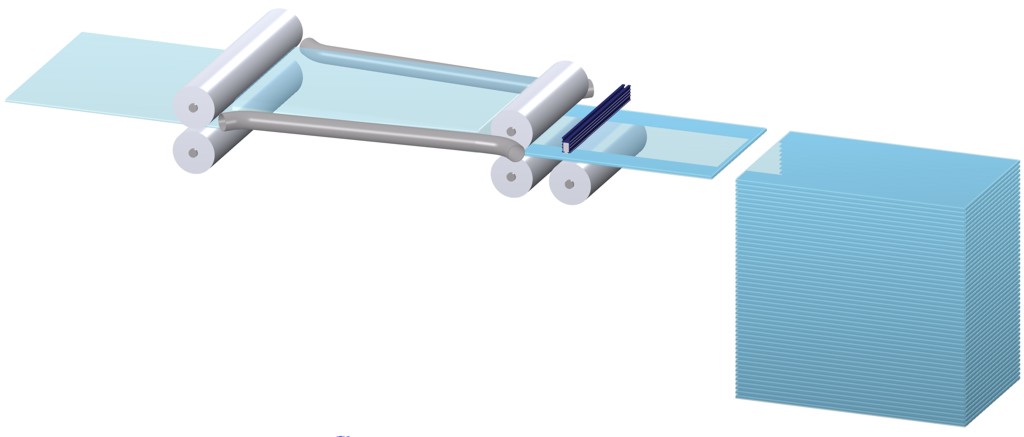

It is possible to electrostatically charge non-woven filter materials to reach higher production speed and to reach better filtration results by attracting/bounding the contamination to the material.

Examples

• Filter material for industrial use (for dust particles and vapor/vapour filtration)

• Filter material for medical use (for mouth masks/caps/lab coats/overalls)

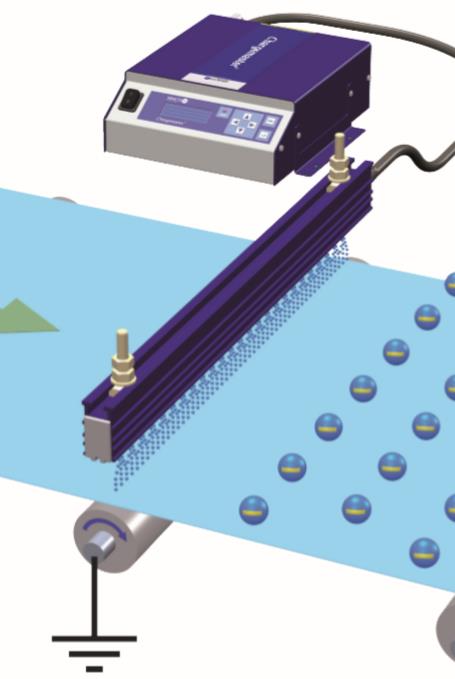

Manufacturers from non-woven filter material and producers from end-products in this industry are using Simco-ION charging equipment to charge the material. The use of electrostatic charging equipment at this application is twofold:

• To charge the filter material to reach better filtration results by attracting/bounding the contamination to the material when used at the end-user

• To bound (orientate) several layers and materials together, to reach higher production speeds, so higher machinery outputs

Note: Drawings and pictures do not show the application one to one, but clarify the situation and approach reality

To charge filter fiber you can uses the CM5-30 high voltage charging generator, in combination with the HDR charging bar is a proven solution.

The use of above mentioned charging equipment increases the output from the machine and the filtration quality from the product so results in high quality competitive filter production.

We offer also a series of High Voltage Generators from 0-60kV ( KiloVolt) that can be used for this principle: Please check our product pages for information on the different type of high-voltage generators.

Find a Simco representative near you.

Please visit www.simco-ion.co.uk or subscribe to the Simco Netherlands Youtube channel